An air pressure gauge is a device used to measure the air pressure exerted by the air or other similar gasses. This device is mechanical and translates a pneumatic system’s force into a visual dial indicator calibrated for representing the air pressure. Read More…

At AMETEK® U.S. Gauge, PMT Products, we take pride in designing and manufacturing precision pressure gauges that set the standard for performance and reliability. We specialize in creating instruments that deliver accurate readings under the most demanding industrial conditions, ensuring dependable operation across a wide range of applications.

We take pride in offering a wide range of pressure gauges designed to deliver precision, reliability, and durability across industrial applications. At Emerson, we engineer our gauges to meet the demands of challenging environments where accurate pressure monitoring is critical to performance and safety.

Since 1946, WIKA has continuously advanced instrumentation for pressure, temperature, level, flow, and force measurement. A global leader in lean manufacturing, WIKA has manufacturing locations around the globe, which enables flexibility and the ability to meet high delivery demands.

Ashcroft’s extensive product line is the benchmark in pressure and temperature measurement, including pressure gauges. Used globally in the most demanding environments, our instruments are known under the names Ashcroft®, Heise®, Willy® and Weksler® and offer multi-industry versatility. As a leader in technology and innovation, we design new products for current and emerging market...

Endress + Hauser makes highly accurate equipment with electric output signals, which function as digital process pressure and differential pressure gauges. Our differential pressure gauges measure dusts, gases, liquids and vapors. Ceraphant is our pressure switch used in absolute and pressure gauges.

More Air Pressure Gauge Manufacturers

Working Principle of Air Pressure Switches

Air pressure switches are critical components in a wide range of pneumatic and industrial automation applications. The core function of an air compressor pressure switch is to regulate the operation of air compressors by monitoring air pressure and activating or deactivating the compressor motor as needed. Inside the pressure switch assembly, there is typically a diaphragm or piston mechanism and a pressure switch relief valve. This relief valve plays a vital role in facilitating easy machine startup by releasing residual line and head pressure, which prevents motor overload and ensures a smooth reset cycle. When the air compressor is powered on, the operator sets the control lever to the automatic position, which triggers the motor to start and begins the compressor pressurization process. As air is compressed and pressure in the tank rises, the system reaches a pre-set cut-out threshold.

At this cut-out pressure, the internal diaphragm within the pressure switch breaks the electrical circuit, stopping the compressor motor. Simultaneously, any built-up back pressure is vented through the pressure relief valve. As the compressed air is consumed or leaks from the system, the pressure gradually drops to a predetermined cut-in level. When the air pressure falls below this cut-in point, the electrical contacts inside the switch close, restarting the compressor motor to replenish the system pressure. This automatic cycling process continues, maintaining optimal air pressure for a consistent supply to downstream equipment or pneumatic tools.

Different types of air pressure switches, including mechanical, electronic, and differential air pressure switches, operate using similar fundamental principles but may offer variations in features such as switching accuracy, response time, pressure sensing mechanism, and integration with digital monitoring systems. The choice of switch type often depends on the specific needs of the air compressor system, environmental factors, and application requirements.

Understanding how an air pressure switch works is essential for maintaining safe and efficient operation of compressors and pneumatic equipment. Malfunctioning switches can lead to unsafe over-pressurization, equipment damage, or inefficient energy use. For industrial operators, facility managers, and OEM engineers, correct selection, adjustment, and maintenance of air pressure switches is a fundamental aspect of pneumatic system reliability.

How to Select an Air Switch

Choosing the right air pressure switch for your application involves a careful evaluation of operating conditions, technical requirements, and control objectives. Selecting an air switch is not one-size-fits-all; your decision should be based on several critical factors that impact system performance, safety, and lifecycle cost.

- Action Type: Determine if your application requires a latching (maintains state until reset) or non-latching (momentary action) switch. Latching air switches are ideal for applications needing sustained switching without continuous pressure, while non-latching switches respond to transient pressure changes.

- Switch Configuration: Assess the number of switches, their ratings (current and voltage), and contact arrangements (single-pole, double-throw, etc.). This depends on what you intend to control—be it a relay, electric motor, low voltage electronic controller, or other load types. Consider the load's inrush current and operational voltage when specifying switch ratings.

- Sensitivity & Sensing Distance: The maximum working distance is influenced by the length and diameter of PVC tubing between the air actuator (air button) and the air switch. Sensitivity decreases with increased tube length or smaller air button volume. For applications requiring quick or precise response, minimize tubing length and select an appropriately sized air button.

- Air Button Volume: Avoid pairing small-volume air buttons with long tubing, as this combination can reduce switch responsiveness. High-rating (high current) air pressure switches should be used only with short tubing distances to maintain reliable actuation.

- Media Compatibility: Ensure the switch materials are suitable for the specific air quality (dry, lubricated, or contaminated air). Corrosive or moisture-laden environments may require switches with specialized seals or enclosures.

- Pressure Range: Select a switch with a pressure setpoint range that matches your system’s operational requirements. Consider both the minimum (cut-in) and maximum (cut-out) setpoint values, as well as differential (deadband) adjustment capabilities.

- Certifications & Standards: For regulated industries or hazardous environments, verify that the air pressure switch complies with relevant standards such as UL, CSA, CE, ATEX, or IECEx.

When evaluating air switches for industrial, commercial, or residential use, also consider anticipated duty cycles, environmental protection ratings (IP/NEMA), and the ease of calibration or adjustment. Consulting with manufacturers or experienced distributors can help ensure the chosen switch aligns with application demands, maintenance expectations, and safety compliance.

How to Adjust an Air Pressure Switch

Proper adjustment of an air pressure switch is essential for achieving the desired system performance and safety. Most air compressor pressure switches feature an adjustable main spring and, in some models, a secondary differential spring. These are typically located inside the protective cover of the switch. Follow these steps to fine-tune your air pressure switch’s cut-in and cut-out settings:

- Access the Adjustment Screws: Disconnect electrical power for safety. Remove the switch cover to reveal the adjustment screws, usually labeled for cut-in, cut-out, and sometimes differential adjustment.

- Increase or Decrease Pressure Setpoints: Turning the main spring screw clockwise typically increases the cut-out (maximum) pressure, while counterclockwise reduces it. The cut-in (minimum) pressure can often be adjusted in a similar manner, or by manipulating a separate differential adjustment screw.

- Set Differential (Deadband): The differential is the difference between cut-in and cut-out pressure. Some advanced air pressure switches allow you to independently adjust this range, which can be useful for applications requiring tighter control or energy savings.

- Test System Performance: After making adjustments, restore electrical power and observe compressor cycling. Use an accurate air pressure gauge to verify actual system pressure at cut-in and cut-out points. Adjust as needed for optimal performance.

Always consult the manufacturer's documentation for the specific adjustment procedure and recommended pressure ranges for your switch model. Improper adjustment can lead to compressor short-cycling, premature wear, or safety hazards.

How to Test an Air Pressure Switch

Routine testing of air pressure switches is crucial for preventive maintenance and ensuring reliable operation of air compressor and pneumatic systems. A faulty pressure switch can cause system failure, equipment damage, or pose safety risks. To test an air pressure switch, follow these detailed steps:

- Disconnect Power: Begin by unplugging the system or switching off the circuit breaker to ensure safety.

- Remove Switch Cover: Use a screwdriver to detach the pressure switch cover, typically by removing a center screw.

- Identify and Prepare Wires: Locate the blue or brown wires running from the switch to the terminal block. These wires may need to be cut or disconnected for testing. Do not cut power supply wires (white and black).

- Apply Test Pressure: Connect a source of controlled air pressure to the switch input port. This can be done using a hand pump or compressed air line with a regulator.

- Check Electrical Continuity: Using an ohmmeter or continuity tester, connect probes to the loose wires. As pressure is applied and the switch actuates, the electrical circuit should close (showing zero ohms or continuity). If the switch fails to close or open at the expected pressure, it may be faulty.

- Adjust Setpoint as Needed: If necessary, use the setpoint screw to recalibrate the switch for proper operation.

- Reassemble and Restore Power: Once testing and adjustments are complete, securely close the switch cover and restore electrical power.

Regular testing helps identify worn or malfunctioning switches before they impact operations. For critical systems, consider implementing a preventive maintenance schedule that includes periodic switch testing, calibration, and inspection of electrical and pneumatic connections.

Applications of Air Pressure Switches

Air pressure switches are versatile devices found in countless industrial, commercial, and residential systems. Their primary function is to provide real-time electrical feedback or control signals based on the rising or falling air pressure within a system. By accurately sensing pressure thresholds, these switches protect equipment, automate processes, and enhance operational efficiency. Explore some of the key application areas below:

Compressed Air Systems

In compressed air systems, air pressure switches are indispensable for maintaining target pressure levels and ensuring the compressor does not exceed safe operating limits. They automatically start or stop the compressor motor in response to pressure fluctuations, preventing issues such as excessive wear, overheating, or tank over-pressurization. Industrial air compressors in manufacturing, automotive, and construction settings all rely on robust pressure switch controls for daily operation.

HVAC Equipment

Heating, ventilation, and air conditioning (HVAC) systems use air pressure switches to monitor and control air flow, filter status, and system safety. In both commercial and residential HVAC units, these switches detect minimum and maximum pressure setpoints, enabling automatic shutdown or startup of fans, blowers, and compressors as required. For example, in air conditioning systems, a pressure switch can prevent compressor operation if refrigerant pressure is too high or too low, protecting the system from damage and improving energy efficiency.

Process Equipment

Manufacturing and process industries rely on air pressure switches to maintain continuous, reliable operation of machinery and automated lines. These switches regulate the supply of compressed air or gas, ensuring that production equipment receives consistent pressure for optimal performance. Applications include pneumatic actuators, conveyor systems, robotic arms, and packaging machinery. High-performance switches with rapid response and tight setpoint tolerances are especially valuable in automated environments where downtime is costly.

Pumping Systems

In water and fluid pumping systems, air pressure switches are used to control pump activation and deactivation based on tank or pipeline pressure. For example, in well water systems, a pressure switch ensures the pump only operates when pressure drops below a preset threshold, extending pump life and preventing energy waste. Similarly, these switches are used in booster pump systems, fire suppression systems, and irrigation controls to maintain precise pressure levels and provide automated system protection.

Additional Use Cases

Beyond the core industries mentioned, air pressure switches are found in countless specialized applications, including:

- Medical Devices: Used in ventilators and anesthesia machines to monitor and control air or gas delivery pressure.

- Automotive Systems: Employed in air suspension, braking, and emission control systems to ensure safety and compliance.

- Food & Beverage Processing: Used to automate filling, packaging, and cleaning processes where air pressure is critical.

- Laboratory Equipment: Maintain safe conditions in fume hoods, autoclaves, and pneumatic testing rigs.

- Energy & Power Generation: Monitor and safeguard pneumatic controls in turbines, boilers, and fuel delivery systems.

Choosing the right air pressure switch for a specific application requires an understanding of the process requirements, environmental conditions, and safety regulations. Working with knowledgeable manufacturers or distributors can help you identify switches with the correct pressure range, electrical characteristics, and agency approvals.

Benefits of Air Pressure Switches

Air pressure switches deliver a range of benefits for both industrial and commercial users. Key advantages include:

- Automated System Control: Seamlessly manage air compressor cycles, pneumatic tool operations, or fluid pumping by providing precise on/off control based on pressure.

- Enhanced Equipment Safety: Prevents over-pressurization, overheating, and mechanical failure by triggering alarms or shutdowns if unsafe conditions occur.

- Energy Efficiency: Reduces energy consumption by only running compressors or pumps when needed, minimizing idle time and lowering utility costs.

- Operational Reliability: Minimizes equipment downtime with consistent pressure control, leading to fewer unscheduled maintenance events.

- Customizable Settings: Offers flexibility with adjustable cut-in/cut-out points and differential settings to match diverse application needs.

- Wide Compatibility: Available in various pressure ranges, electrical ratings, and mounting styles for integration into new or existing systems.

- Cost Savings: By protecting major system components, air pressure switches help extend equipment lifespan and reduce replacement costs.

These benefits make air pressure switches a smart investment for process optimization, safety assurance, and total cost of ownership reduction across many sectors.

Decision Factors When Buying Air Pressure Switches

When researching or purchasing air pressure switches, consider the following decision-making factors to ensure you select the best product for your specific needs:

- Pressure Range and Accuracy: Select a switch with a suitable pressure range and accuracy for your system. High-precision switches are often required for laboratory or critical process control applications.

- Electrical and Mechanical Ratings: Ensure the switch can handle the voltage, current, and switching frequency required by your load. Mechanical durability, including cycle life, is also crucial for high-use environments.

- Environmental Conditions: Consider temperature range, humidity, vibration, and exposure to dust or chemicals. Choose switches with appropriate ingress protection (IP) or NEMA ratings for harsh or hazardous locations.

- Mounting and Connection Options: Air pressure switches come in various mounting configurations (surface, panel, DIN rail) and with different port/thread sizes. Select one that fits your installation needs.

- Response Time: Fast-acting switches are essential in dynamic or high-speed pneumatic applications, while slower switches may suffice for basic on/off control.

- Maintenance Requirements: Opt for models that are easy to access, calibrate, and service. Some advanced switches offer digital readouts or remote monitoring capabilities.

- Compliance and Certification: Verify that the switch meets industry standards and certifications required for your sector, such as UL, CE, or ATEX for hazardous areas.

- Supplier Reputation: Purchase from reputable manufacturers or distributors that offer technical support, warranty coverage, and readily available replacement parts.

By carefully weighing these criteria, you can confidently select an air pressure switch that delivers long-term value, optimal performance, and regulatory compliance for your facility or project.

Air Pressure Switches vs. Other Pressure Sensing Devices

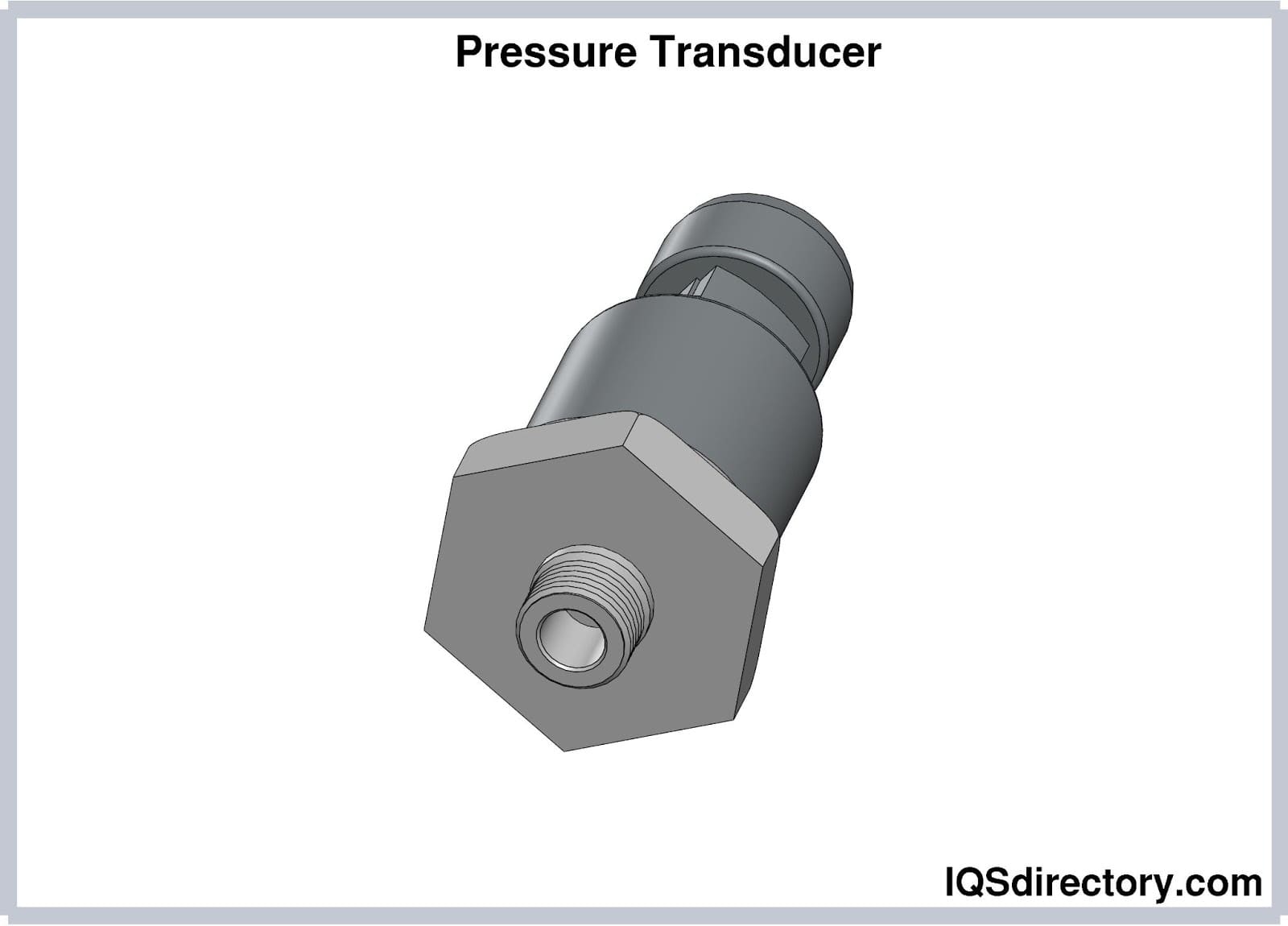

When evaluating solutions for pressure monitoring and control, it’s important to distinguish between air pressure switches and other pressure-sensing devices such as pressure transducers, pressure sensors, and pressure gauges. Each serves a unique function:

- Air Pressure Switches: Primarily used for automatic control—turning equipment on or off at preset pressure points. Ideal for direct, binary switching applications.

- Pressure Gauges: Provide real-time visual indication of system pressure but do not offer automated control.

- Pressure Sensors/Transducers: Convert pressure readings into electrical signals for monitoring, data logging, or integration with programmable logic controllers (PLCs) and building management systems.

For simple start/stop automation, air pressure switches offer a cost-effective, reliable solution. For advanced monitoring, diagnostics, or process optimization, integrating switches with sensors and digital controls can deliver greater visibility and flexibility.

Choosing the Proper Air Pressure Gauge Manufacturer

To make sure you have the most positive outcome when purchasing Air Pressure Gauges from an Air Pressure Gauge Company, it is important to compare at least 5 or 6 Manufacturers using our list of Air Pressure Gauge manufacturers. Each Air Pressure Gauge Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Air Pressure Gauge company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Air Pressure Gauge businesses with the same form.

In addition to comparing manufacturers, consider factors such as product range, custom engineering options, warranty terms, delivery times, and technical support availability. Leading air pressure gauge suppliers often provide value-added services such as calibration, installation assistance, and after-sales service. Researching user reviews and case studies can also offer insight into real-world performance, reliability, and customer satisfaction.

Whether you’re sourcing analog or digital air pressure gauges for industrial, laboratory, or commercial applications, partnering with experienced manufacturers ensures you receive high-quality products tailored to your specifications. Look for suppliers with a proven track record in your industry and the ability to provide support across your project's lifecycle.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services